|

<< Click to Display Table of Contents >> Preset Productivities |

|

|

<< Click to Display Table of Contents >> Preset Productivities |

|

This example involves of the use of a multiple branch Supersequence in a pit which has a pre-strip fleet stripping down to a particular horizon followed by the main fleet removing the balance of waste and uncovering a coal seam. In this case the pre-strip fleet will typically strip one strip in advance. The Subsequences for the pre-strip fleet are in one branch of the Supersequence and the main fleet is in the parallel branch. In such an operation it is necessary that the pre-strip fleet completes the advanced stripping before the main fleet completes stripping in the current strip. The following figures illustrate this:

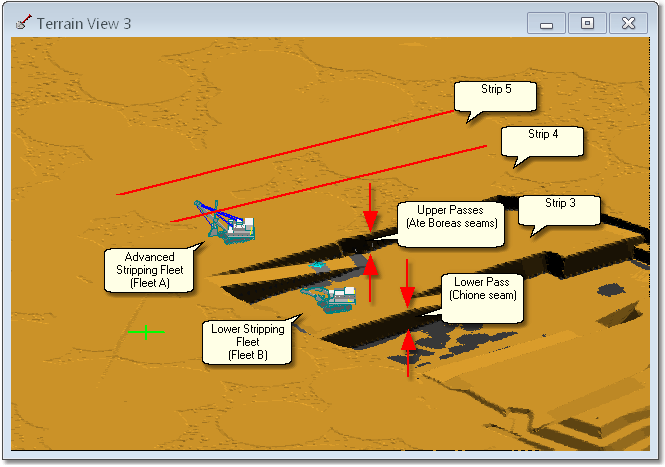

Preset Productivity Example, Pit Layout.

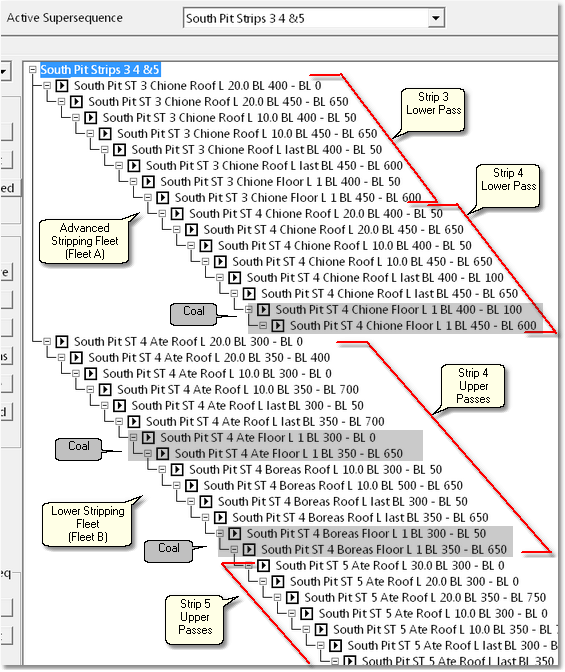

Preset Productivity Example - Supersequence.

In the above example there are two waste stripping fleets and a coal fleet operating. Fleet A excavates the waste of the to upper seams an Fleet B excavates the waste for the lower seam. Fleet A operates one strip in advance of Fleet B. The figure above illustrates the Supersequence. This Supersequence has two branches one for Fleet A and one for Fleet B. In addition a coal fleet is assumed to be available as required. The right-hand branch of the Supersequence is for Fleet A and the left-hand branch is for Fleet B. The sequence commences with the pit in the starting state to excavate the upper waste for Strip 4 and the lower waste for Strip 3. Fleet B excavates Strip 3 lower passes then moves to the Strip 4 lower passes. Fleet A, in parallel, excavates Strip 4 upper passes followed by Strip 5 upper passes. The relative productivity of the two fleets must be such that Fleet A completes the Strip 4 upper passes before Fleet B moves to the Strip 4 lower pass.

This task can be modelled by assigning Preset Productivities. A Preset Productivity would be created and named for the following:

1.Fleet A

2.Fleet B

3.Coal Fleet

The Fleet A Preset Productivity would then be applied to all of the lower pass waste Subsequences, the Fleet B Preset Productivity would be applied to all of the upper waste pass Subsequences and the Coal Fleet Preset Productivity would be applied to all coal Subsequences.

At this stage the simulation would be run and the relative rate of advance of the two waste fleets would be observed. If Fleet A does not perform the required advanced stripping before Fleet B moves to strip 4 lower pass then either the Fleet A productivity needs to be increased or the Fleet B productivity needs to be decreased. The Preset Productivities can be varied in a manner that reflects either different equipment fleet or different shift allocation. In this way the appropriate productivities for the two Fleets can be readily assessed.

3d-DigPlus must be in Auto mode after the tutorial file is loaded:

Simulation Pulldown - Auto Mode

To run this tutorial load the file PresetProd_Start.3dd. The following video clip covers the tutorial material: