|

<< Click to Display Table of Contents >> Truck Optimisation |

|

|

<< Click to Display Table of Contents >> Truck Optimisation |

|

The Truck Optimisation option in Truck Assignment allows optimal truck numbers to be automatically allocated. The user specifies the following:

1.Maximum number of trucks which can be assigned.

2.The percentage of maximum excavator productivity to be targeted.

The maximum number of trucks are assigned in the same manner as per manual truck assignment. The maximum excavator productivity is the productivity of an excavator with a queue of trucks available at all times. The user specifies the percentage of maximum productivity, 3d-Dig then determines what this productivity is and assigns sufficient trucks such that this productivity is met or exceeded.

Once a file is set up to the point where it is ready for truck simulation the following steps are required to implement optimisation:

1.If you require the system to determine the absolute optimum truck number then the number of trucks available must be equal to or greater than the maximum number required to optimise. The best way to ensure this is to use the Equipment Settings to assign a very large number of trucks.

2.If you require the system to determine the optimum truck number subject to a maximum allowable number, then ensure that the number of trucks included in the simulation equals this maximum number.

3.Using the Simulation Settings dialog, ensure that all Subsequences used in the simulation are set to optimise truck numbers.

4.On the Results page of the Simulation Settings dialog ensure that the general and report settings are suitable to produce the optimisation information you require.

5.Run Simulation

The following notes describe these procedures.

From Equipment Setting pulldown on the Toolbar select the Truck option:

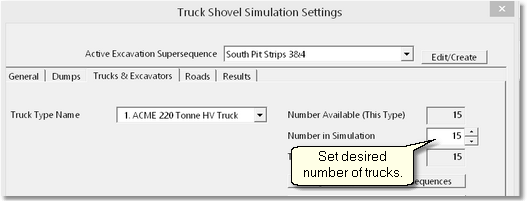

In the Truck Parameters dialog ensure the New Number of This Type is set to a suitably large number or the maximum number of available trucks:

In the Truck and Shovel Simulation Settings dialog, Trucks & Excavators page set the Number of Trucks in Simulation to the desired number. This will either be the maximum number if you wish to have an absolute optimum all the maximum allowable number if you want the optimum number of trucks up to a nominated limit:

Note that when performing the previous step you can set a very large number of trucks for use in the 3d-Dig file, but use the above setting to limit the number in the actual simulation. Hence if you wish to optimise up to given limit you can easily modify the available limit and run the simulation several times to determine the consequences.

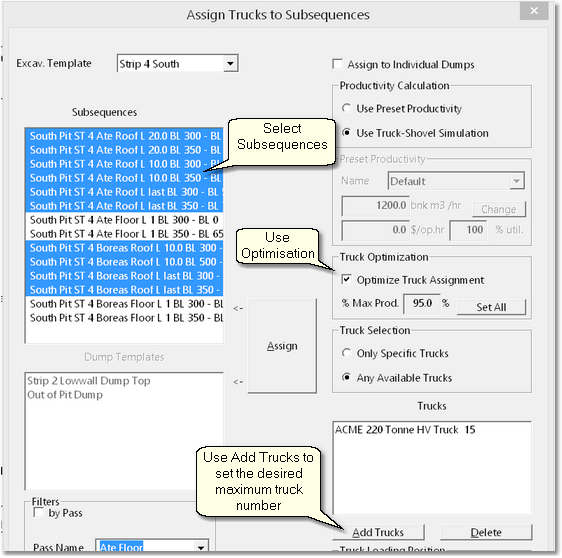

The Optimisation settings are established in the Assign Trucks to Subsequences dialog:

In the Assign Trucks to Subsequences dialog select the desired Subsequences to be optimised. Then check the Optimise Truck Assignment dialog and set the % Max Prod parameter. This will set the percentage of maximum excavator productivity which will be the target for optimisation. Trucks will be added until this productivity is met or just exceeded.

Use the Add Trucks button to set the maximum number of trucks available for the selected Subsequences.

Once the above settings have been established for all Subsequences in all Excavation Templates for which trucks are assigned the simulation is run in the usual manner.

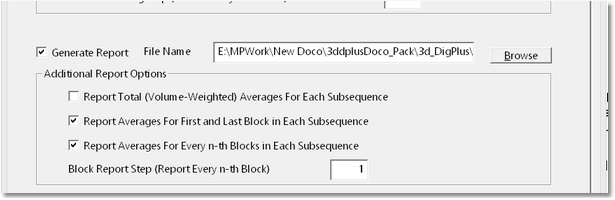

When running and optimised simulation it is generally required to produce report file which lists the optimum truck numbers on a block by block basis. To achieve this select the Results page of the Simulation Settings dialog. Ensure that the Generate Report option is selected and that Report Averages for every nth block is also selected. To report every block the Block Report Step field must be set to 1:

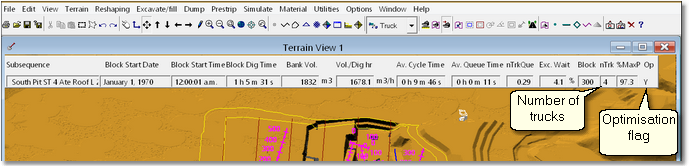

During the simulation the truck optimisation status and the current number of assigned trucks is displayed in the information bar on the top of the Active Window:

Information Bar in Terrain Window during Truck-Optimised Simulation.

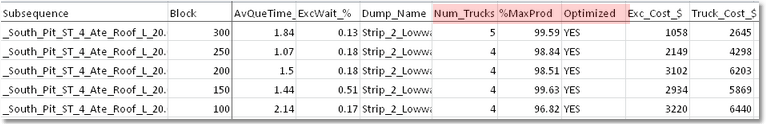

The information bar on top of the Terrain Window will only display every nth block as specified on the Results page. It is generally not feasible to have this display every block as it significantly slows down simulation time. However the block by block truck numbers are reported in the report file as illustrated below:

Truck – Shovel Simulation Report File Sample.