|

<< Click to Display Table of Contents >> Modifying Non-Continuous Coal Seams |

|

|

<< Click to Display Table of Contents >> Modifying Non-Continuous Coal Seams |

|

The issue of of handling coal seams which are not continuous over the area of the excavation is discussed in the topic handling non-continuous coal seams, and this should be read before continuing with the current topic.This topic describes some methods of using 3d-DigPlus functionality to modify non-continuous coal surface and floor models to render them suitable to use in staged excavations.

Critical Information

3d-DigPlus has been developed to perform specialised simulations, it is not a geological modelling package. Hence is recommended that geological merge models are produced in a specialised geological modelling system. However 3d-DigPlus does have some functionality which can extend and modify coal seam models and merge roof and floor together and in the absence of any more suitable option these are available to handle discontinuities.

3d-DigPlus has been developed to perform specialised simulations, it is not a geological modelling package. Hence is recommended that geological merge models are produced in a specialised geological modelling system. However 3d-DigPlus does have some functionality which can extend and modify coal seam models and merge roof and floor together and in the absence of any more suitable option these are available to handle discontinuities.

The typical situation to which this functionality would be applied is where a particular coal seam is only viable within some of the area of an excavation. in such cases it is desirable to have the coal surface extend out over the area of discontinuity and to have the roof and floor models merged to the same level in this area. In this manner it is easy to create an excavation which,in the region of non-viable coal, extends down to the general level of the coal roof and as the roof and floor are the same in this area is not possible to inadvertently mine non-viable coal.

There are two cases which can apply here:

1.The coal seam model only exists with the coal is viable and is not exist elsewhere within the excavation area.

2.The coal seam model (roof and floor) is continuous throughout the area of the excavation but coal will only be mined in a sub area within the excavation.

Case 1 requires that the coal seam (roof and floor) be extended extrapolated out to cover the area of the excavation.

Case 1 and 2 require that the roof and floor of the seam be merged together in the area with a coal is not viable so the staged excavation will not excavate the coal in this area.

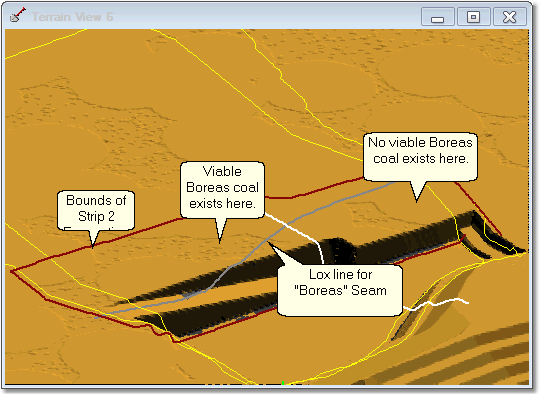

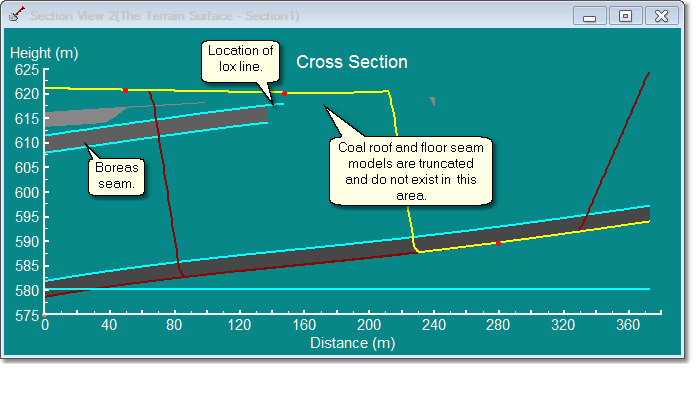

The following figures illustrate a pit with a coal seam truncated at the lox line:

Boreas seam data:

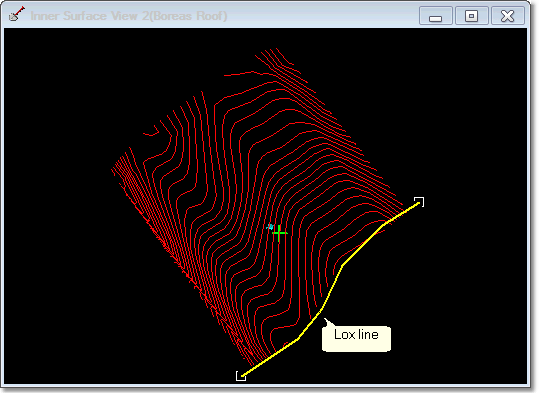

As can be seen in the figure above the data for the coal seam ends at the lox line. The procedure for extending the model involves fabricating additional data to place beyond the lox line limit. The roof and floor are treated individually with the same process, the following steps are used:

•Open a Data Window to view the source data for the coal roof model.

•Use the add Data Features command to draw a data feature at the very end of the surfaces data approximately along the lox line (make sure this line is at least slightly inside the bounds of the data). This feature will be located on some level distinct from the surface data

•Use the Features/Drape All command to drape the newly created data feature on to the coal roof surface.

•Use left click and drag to move this newly created feature away from the existing data and in to the area where data are required.

•When complete re-triangulate and re-grid surface.

The following annotated video clip demonstrates these steps:

In areas where coal does not exist or when mining of the coal is not viable we have to merge the roof and floor models to a common surface. Generally the roof model is the common surface.

General procedure involves using 3d-Digs Excavate/Fill command to modify the coal floor model in the required region to make it consistent with the roof model in this area. Generally when using the Excavate/Fill command we are working on the Terrain Surface. However 3d-DigPlus does not restrict the user to modifying the terrain surface with Excavate/Fill and any inner surface is a candidate for this command.

The steps involved are:

1.In the Terrain Window locate the appropriate lox line (line delineating area to be merged) and copied to the clipboard.

2.Open up a rendered view window to the surface to be modified (usually the coal floor).

3.Set up an excavation template bound to the "merge to" surface (usually the coal roof).

4.Draw an Inner Excavation Polygon closely following the lox line and encompassing the area to be merged.

5.Excavate to merge the surfaces.

The following video clip demonstrates the procedure using the pit and coal surfaces described and used above. the Boreas Seam floor is to be merged with the Boreas Seam roof in the area beyond the lox line: