|

<< Click to Display Table of Contents >> Handling Non-Continuous Coal Seams |

|

|

<< Click to Display Table of Contents >> Handling Non-Continuous Coal Seams |

|

On occasions one or more of the coal seams within a Staged Excavation will not be continuous over the full area of the proposed excavation. There are two modes of orientation for discontinuity:

1.Coal seam extends across the full width of the strip but not over the full-length.

2.Coal seam does not extend across the full width of the pit in some or all of the strip length.

Frequently the discontinuity is a combination of 1 and 2. In case 1 where a coal seam does extend across the full width for some of the length of pit but is absent across the full width in other areas 3d-DigPlus will, at the stage of forming a raw sequence, simply produce raw sequence steps wherever the coal is present and produce no steps where it is absent.

The case 2 is more complex.

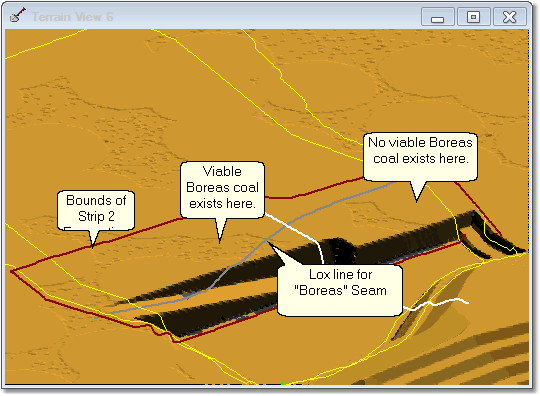

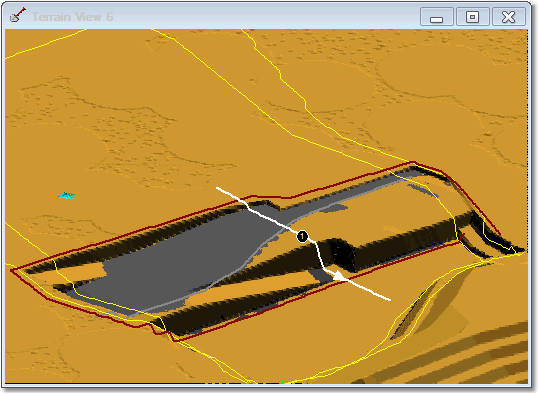

A common example of this situation is where an upper level coal seam is encountered for the first time in a particular strip. In this situation it is often the case that the line of demarcation between viable and non-viable coal (typically the lox line) will pass within the excavation area such that some of the excavation area has mineable coal and some does not. The figure below illustrates the situation:

In the above example strip 2 for this particular pit is the next the excavated. In strip 1 seam at the floor of pit was uncovered, and in strip 2 a higher level seam (Boreas seam) exists for part of the strip. The lox line pounding viable and non-viable coal for the Boreas seam can be seen in the above figure, part of the excavation area has viable coal and part does not.

The methods used to handle this situation depends on the nature of the geological model. there are two distinct situations which may exist:

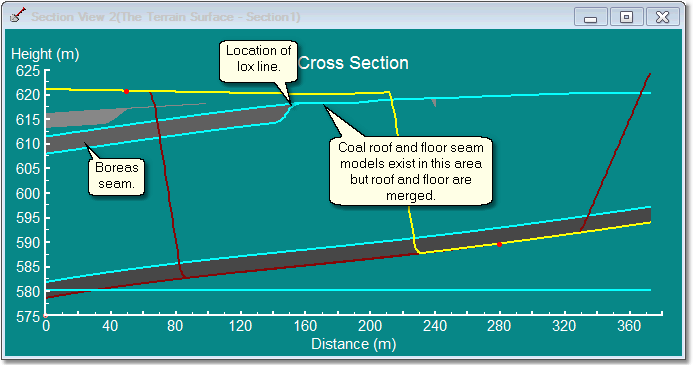

1.A geological merged model exists. With this type of model coal seam roof and floor are continuous over the full area of the proposed pit and strips. Were coal is not viable the roof and floor of the coal seams have the same level and topology,where the coal is viable the roof and floor diverge by the coal thickness.

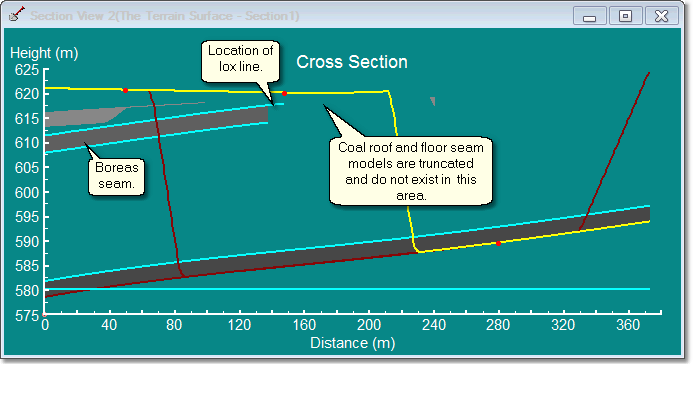

2. Coal seam models are truncated where coal is not viable.

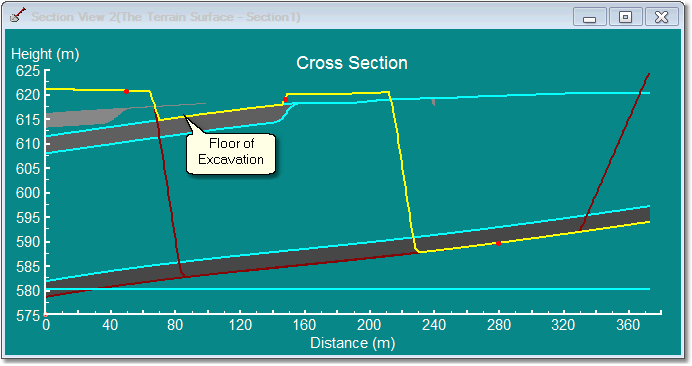

The following cross-section illustrates a coal seam merged model in cross-section:

The following figure illustrates a model with truncated coal seams:

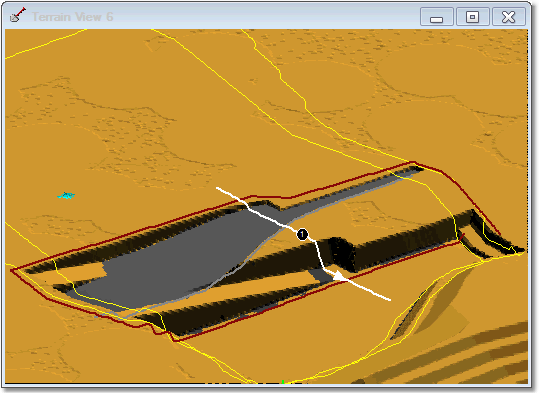

The following figures illustrate the results of excavating strip to the Boreas seam roof using truncated and merged models.

Excavation with truncated model:

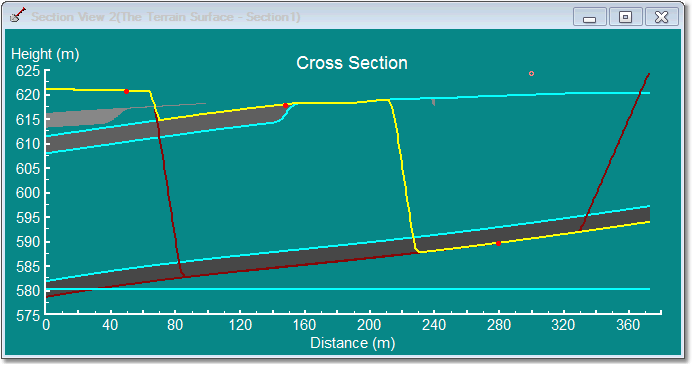

Excavation with truncated model cross-section:

Excavation with merged model:

Excavation with merged model cross-section:

As can be seen in the above figures, when excavation to a coal seam takes place and the coal model is truncated and non-continuous throughout the area of excavation, waste is excavated from above the coal seam (in the region where the model exists) and is left intact elsewhere. This is because there is no information to tell 3d-DigPlus what level to excavate to beyond the area with a coal model exists.

In cases where a thin waste seam is excavated the above approach may represent the mining process with sufficient accuracy. But where waste is thick it is highly unlikely that a deep waste excavation will be performed only within the area of the coal seam and adjacent waste left intact. It may be possible in some cases to design a bench at approximately the same level as the coal roof and to excavate waste to this bench level. However in cases where the coal seam surface shape is complex this process will be difficult. The recommended approach is to use a coal seam merged model. This will make the process of setting up excavation is in 3d-DigPlus much easier and will ensure that excavation to the roof of coal seams which are discontinuous will be modelled in a realistic manner consistent with mining practice.

3d-DigPlus has been developed to perform specialised simulations, it is not a geological modelling package. Hence it is recommended that merge models are produced in a specialised geological modelling system. However 3d-DigPlus does have some functionality which can extend and modify coal seam models and merge roof and floor together and in the absence of any more suitable option these are available to handle the above discontinuities. These methods are explained in the following topic Modifying Non-Continuous Coal Seams.