|

<< Click to Display Table of Contents >> Staged Excavation Steep Dip. |

|

|

<< Click to Display Table of Contents >> Staged Excavation Steep Dip. |

|

In this exercise we will set up an automated excavation sequence via a Staged Excavation to model the excavation of the North Pit Strip 2. The sequence we will model is as follows:

•The strip will be excavated from topography to the floor of the coal seam via horizontal Lifts spaced vertically at 10 m.

•The Waste for each Lift will be sequentially excavated until the first bench level is reached at which coal is exposed.

•On completion of the waste excavation for the first bench at which coal was exposed, the coal will be mined to the level of the bench.

•Waste from the following bench (10 m lower) will be excavated and the coal for this bench exposed.

•The exposed coal in this bench will be mined to the level of the bench.

•This procedure will continue until the strip is mined out.

The procedures for setting up the Staged Excavation for the North Pit Strip 2 are similar to those used in the previous topics for the South Pit. However the key difference is that in the South pit example the coal for each pass was fully exposed before being mined. As a result each Lift of each Pass was either a dedicated waste lift or a dedicated coal lift. In this steep dip example, once waste stripping reaches the the level of the highest point in the coal roof (ie the first lift which exposes coal), for this and subsequent benches both waste and coal will be mined on each bench. We must therefore be able to create a Supersequence that allows the waste for a particular bench level to be excavated followed by the coal at that bench level. This is achieved by creating separate Subsequences for the excavation of waste and coal at each bench level . Once the coal level has been reached each subsequent bench is excavated via two Subsequences, one for waste removal and one to remove the coal for that bench level. The Supersequence will consist of the following structure:

•Excavate the Subsequence for the waste for a particular bench level.

•Excavate the Subsequence for the coal for the same bench level.

In order for the above procedure to work Subsequences must be given a name which clearly indicates the bench to which they belong. This allows the sequential excavation of waste Subseaquences then coal Subsequences for each bench.

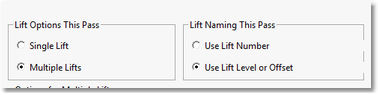

The key to being able to easily create these Subsequences is in the settings we use for the naming of the elements in the Raw Sequence. On the Staging page of the Excavation Template dialog there is a group of radio buttons titled Lift Naming This Pass:

Excavation Template Dialog, Staging Page Lift Naming Group.

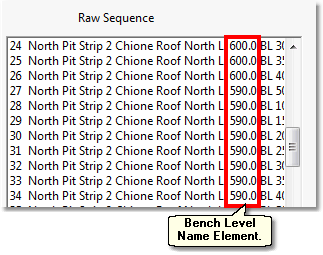

We will be using the option Use Lift Level or Offset. We will also be using the benching option which will result in horizontal benches at fixed levels. As a consequence of these settings the raw sequence, and ultimately the Subsequences, will have an element in their name which indicates the lift bench to which they belong. The following figure shows portion of the raw sequence showing this naming element:

Excavation Raw Sequence Showing Bench Level Name Element.

In the figure above the Raw Sequence Steps towards the top have the bench level name element of 600.0, this indicates that they belong to the bench at RL 600.0.

Once the Raw Sequence Steps contain a naming element indicating the bench to which they belong, the Subsequence naming rule can be set up to use this element and so the Subsequences will inherit this naming element.

The lift Naming option Use Lift Number, simply gives the benches an integer number progressing from the top (highest) bench down. So for example, if there was five benches in a pass the first would be numbered '1' and the last '5'. This naming method is suitable for mining operations were each pass is excavated to completion prior to excavating the following pass. However it provides no means of coordinating lifts between passes or between subsequent strips.

This topic involves the following tasks:

•Load the 3d-DigPlus file Steep Dip Tutorial 1.3dd

•Set up a Pit and Block Lines for the North Pit.

•Establish an Excavation Template for the North Pit Strip 2

•Set up the Staged Excavation Settings for Strip 2, including the appropriate Lift Naming Rule.

•Create the Raw Sequence for Strip 2.

Load the File 'Steep Dip Topic 1.3dd', whe

The following video clip illustrates these tasks:

3d-DigPlus must be in Auto mode after the tutorial file is loaded:

Simulation Pulldown - Auto Mode

Load the File 'Steep Dip Topic 1.3dd, when the exercise is complete save the 3d-DigPlus file under the name: 'Steep Dip Topic1_Complete.3dd

Creating Subsequences for a Pit with Steep Dip.