|

<< Click to Display Table of Contents >> Automated Dragline - Priciples of Operation |

|

|

<< Click to Display Table of Contents >> Automated Dragline - Priciples of Operation |

|

For the purposes of setting up the automation, the dragline operation must be subdivided in a logical manner consistent with field of practice. The following key elements/terms are used in this process:

•Block. A block is the smallest complete increment of the dragline operation. It corresponds to the term block or patch as used by dragline operators. In this system block also relates to the pit block lines as these are used to establish the simulation blocks.

•Boom Dump. Boom Dump is a dump line located under the draglines dump radius on which material is dumped. It corresponds to a conventional dragline dumping mode.

•Bench Dump. Dragline benches are typically constructed via a combination of dragline dumping, dozing and possibly dragline raking of dumped material. It is possible to form a bench by dragline boom dumping followed by dozing. In situations where the dragline operating method completes a pass leaving spoiling in-pit for subsequent bench dozing, the dump is formed by initially dumping with the dragline and subsequently dozing. However where the bench is formed incrementally as part of the operating method the Bench Dump dump type is used. This dump type simulates the dumping of the dragline and dozing in one manoeuvre to form a complete bench increment.

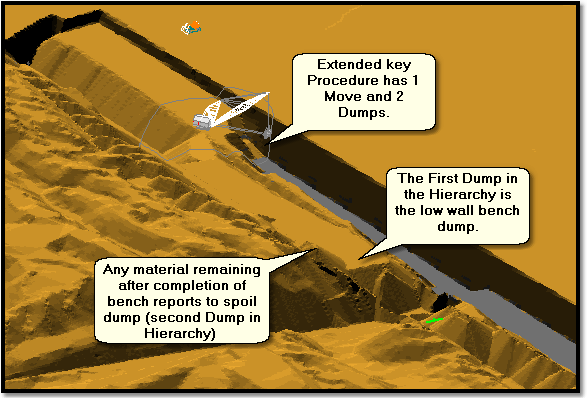

•Move. This is an individual (single) elemental excavation and associated dump hierarchy. It could be a key cut, trim cut or low wall excavation etc. Note that this definition of Move is different from the dragline walking from point to point, this is referred to as Positioning and described below. This is referred to as Positioning and described below.

•Procedure. This is a series of moves required to complete the current block in the current Sub-Pass. A procedure can consist of a single Move or a series of Moves

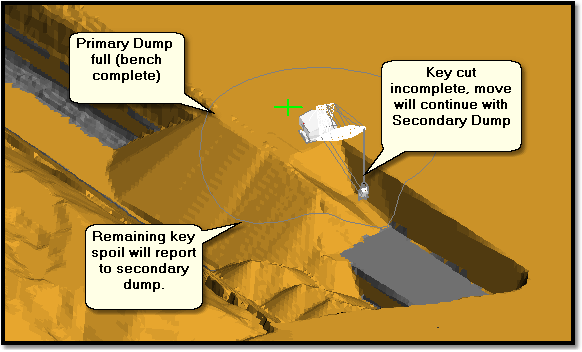

•Dump Hierarchy. Frequently when conducting a Move, the dragline will need to dump to a number of locations. For example, if building a bench, material will initially report to the bench until this is complete, when the bench is complete material may report to a final spoil boom dump. Each Move has a number of Dumps assigned in order of priority, and these are referred to as the Dump Hierarchy.

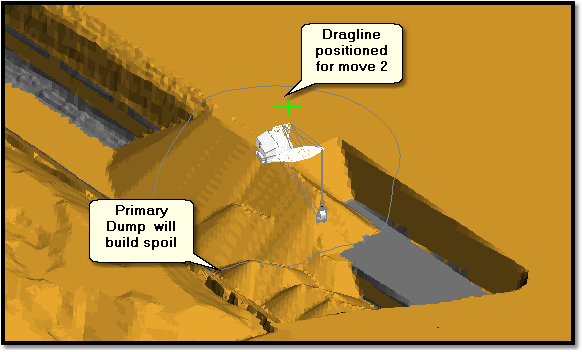

•Macro Positioning. Once the system establishes a particular Move for a Block it must determine the position from which the dragline will excavate and dump. This is done via a number of user specified parameters and are Positioning Line.

•Position Indexing. Dragline will typically dig a particular excavation from a number of top positions. These may be associated with an initial position which allows the drag chain limits to be cleared, followed by walking up to the dig face. In other situations the dragline may need to range over a number of positions for particular spoiling requirements. This type of incremental positioning is referred to as Position Indexing and is automatically established using a series of user defined parameters.

•Pass. This is the same definition of Pass as used in Staged Excavations. It will typically be the complete excavation which covers a coal seam.

•Sub-Pass. This is a contiguous set of Proceedures. An example of Sub-Pass would be a contiguous set of key cut excavations which created a key cut from block 0.0 to block 500.

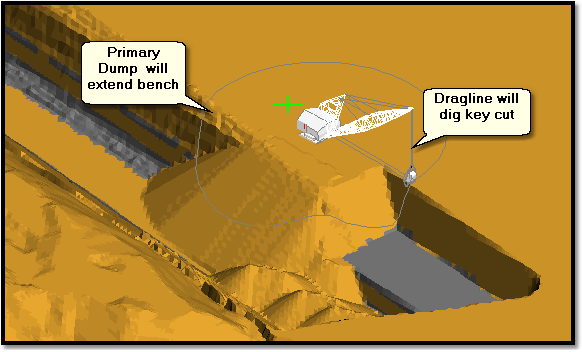

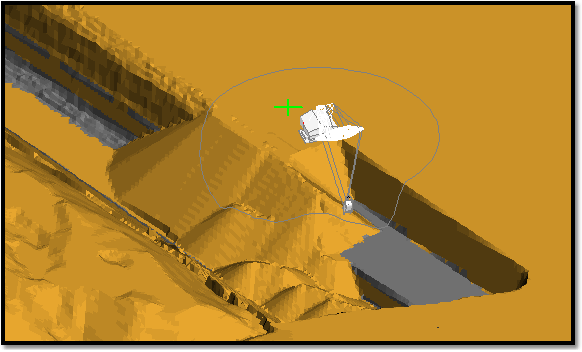

The following diagrams and notes illustrate the above terms in the context of a typical dragline operation. Note that in these examples only Macro Positioning is shown for simplicity.

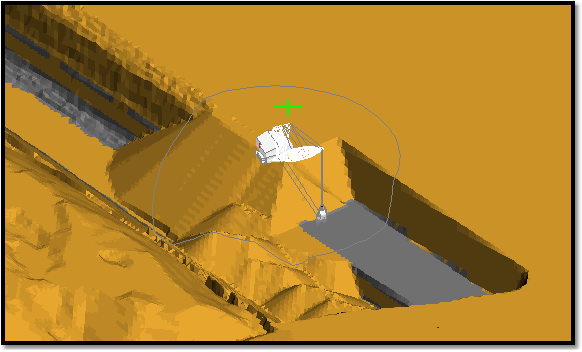

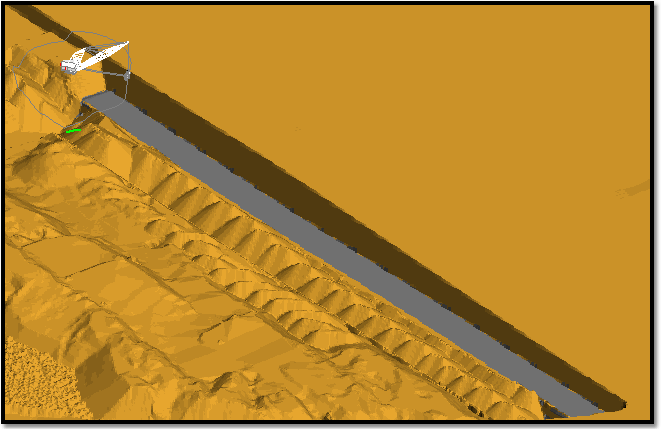

The following figures illustrate a first pass (of two passes) operation in which the dragline uses a key bench method to uncover and upper coal seam. The dragline initially positions itself to dig the key cut, and excavates and dumps to extend bench. When the bench is complete the balance of the key cut excavation is excavated and dumped in pit the spoil. Once the key cut is complete the dragline repositions to the edge of the bench and excavates the remainder of the block casting it to and in-pit spoil pile.

Key Bridge Procedure - Move 1 Dump 1 start. Excavate key cut and extend bench.

Key Bridge Procedure - Move 1 Dump 2 Complete. Bench Complete, Key Cut Incomplete.

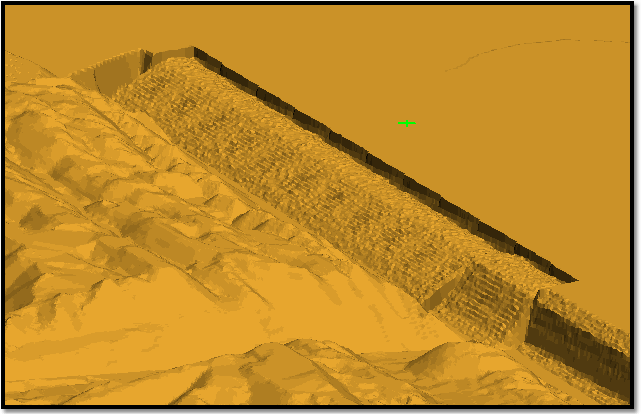

Key Bridge Procedure - Move 1 (Key cut) Complete.

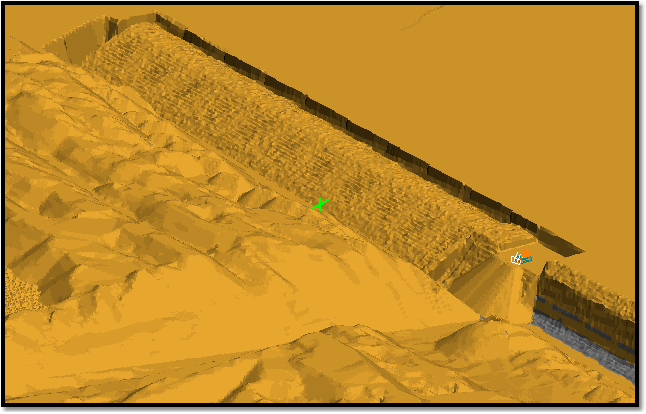

Key Bridge Procedure - Move 2 Low Wall Excavation Start

Key Bridge Procedure - Move 2 Low Wall Excavation Complete, Key Bridge Procedure Complete.

Key Bridge Procedure - Key Bridge Sub-Pass Complete.

The following slides illustrate the construction of a dozed bench from a blast profile. Each Procedure consists of one Move in which material is excavated from the block, to bench level, and dumped.

Dozed Bench Procedure, Start of Procedure.

Dozed Bench Procedure, Completion of Move and Procedure - Block 1.

Dozed Bench Procedure, Completion of Sub Pass.

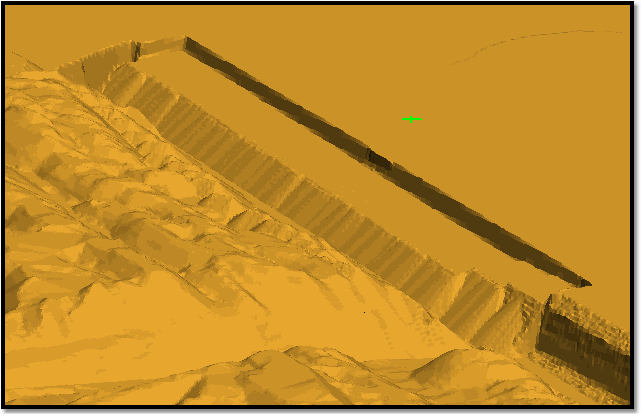

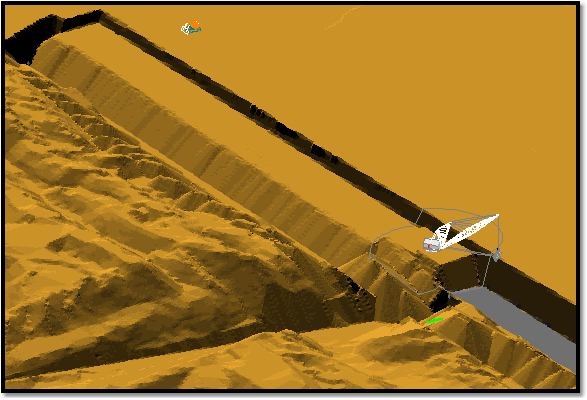

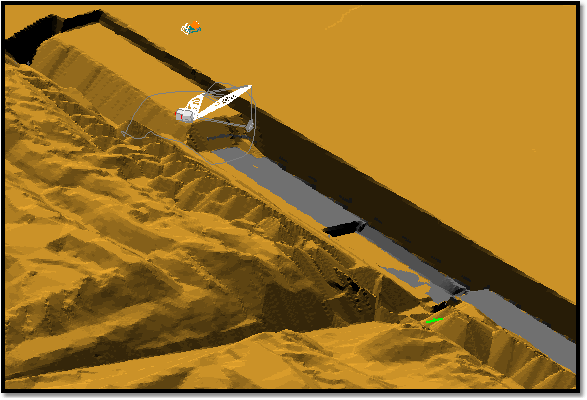

The following pictures illustrate an extended key/low wall bench operation which is conducted on the dozer the bench illustrated above. This operation has two Sub Passes, one for the extended key/bench operation and a second for the low wall operation.

Extended Key Sub Pass Start.

Extended Key Sub Pass Complete, Low Wall Sub Pass Start.

Low Wall Sub Pass Complete.